Empowering Smart Transportation: Sailsky's Success in Delivering an Intelligent Inspection System for a Cross - sea Bridge, with Industrial Wireless Technology Solving Communication Hurdles in All - metal Environments

Amid the global trend of large - scale bridge construction, cross - sea bridge safety and maintenance are industry concerns.

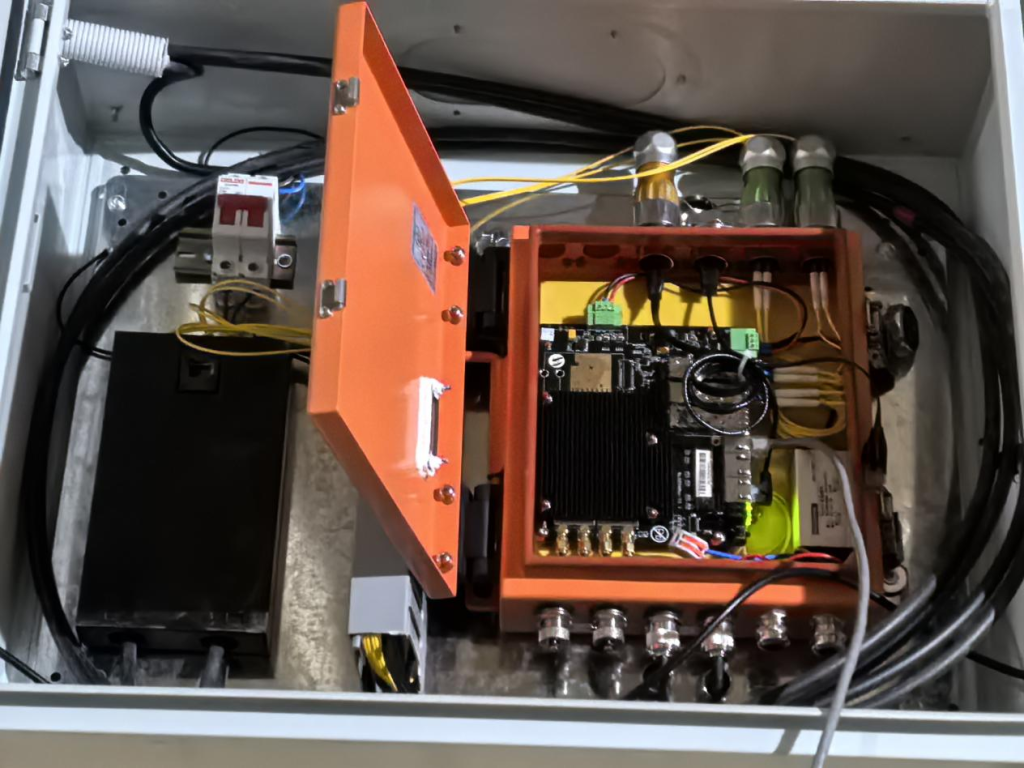

Recently, our company Sailsky, using its self - developed wireless tech, won and completed a cross - sea bridge intelligent inspection project.By deploying the BL6000MAX AP and sensor solutions, we achieved bridge intelligent inspection, overcame signal issues in metal spaces, and set a new benchmark for large - scale infra digital O&M

Project Background and Challenges

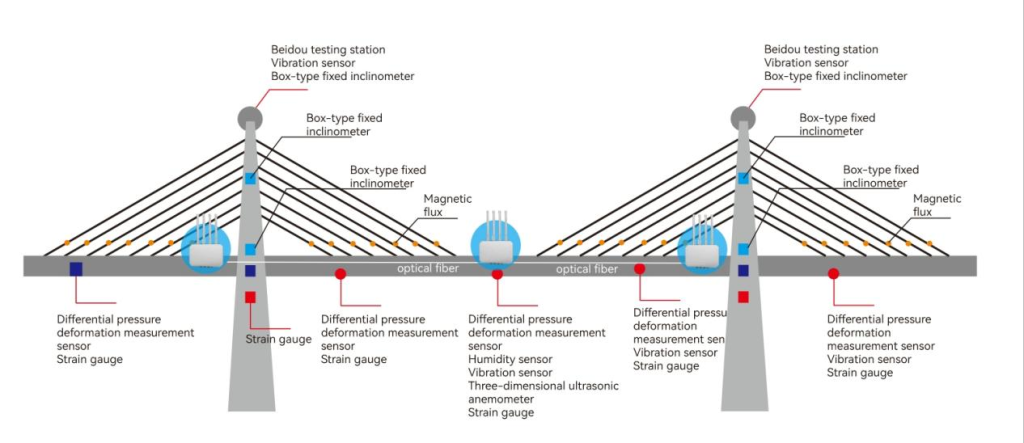

The main structure of this cross - sea bridge features a fully steel design. The bridge's steel structure creates a high-density metal environment in its inspection passage, posing significant wireless communication challenges:

- Severe Signal Shielding: The metal structure induces electromagnetic wave reflection and co - frequency interference. As a result, the coverage of conventional WiFi is highly unstable, with low data transfer rates and a high data packet loss rate.

- Stringent Real - time Operation and Maintenance Requirements: The system needs to support hundreds of vibration, temperature and humidity, and stress sensors to continuously transmit data around the clock, placing exacting demands on network stability.

Core Solutions: Industrial - grade Wireless Technology + Scenario - specific Innovation

Our tech team offers a three-in-one solution combining hardware, algorithms, and networking to address these project challenges.

BL6000MAX Industrial Wireless AP: Full - scale Coverage Capability

- Exceptional Penetration Performance: By applying beamforming technology, it can achieve stable signal penetration and coverage within the partitioned metal corridors, enhancing the signal strength by 40%.

- Military - grade Anti - interference Design: Equipped with a powerful signal processing algorithm, it can monitor environmental interference sources in real - time and automatically adjust signal strength and frequency.

- Industrial Environment Adaptability: With an IP68 protection rating and the ability to operate within a wide temperature range from - 40°C to 75°C, it can effectively withstand the high - salt - fog and humid marine environment.

Project Achievements and Value

- Comprehensive Coverage with No Blind Spots: We have successfully achieved continuous WiFi6 coverage along the 5 - kilometer inspection passage inside the bridge body. The system has been operating continuously and stably, reducing the failure rate.

- Revolution in Operation and Maintenance Costs: By replacing the traditional fiber - optic deployment scheme, the construction period has been shortened by 70%, and the overall cost has been reduced by 45%.

- Enhanced Safety and Efficiency: Real - time monitoring data is directly connected to the cloud - based management platform, enabling the identification and response to potential structural risks to be accelerated to the minute level.

Customer Testimonial

Your company's industrial wireless solution has demonstrated outstanding technical prowess in the harsh all - metal environment. The system's post-operation stability surpassed expectations, reliably supporting the bridge's lifecycle health management

Conclusion: Harnessing the Power of Industrial Internet to Build a Smart Future for Infrastructure

This cross-sea bridge project confirms our wireless technology leadership in complex industrial applications.

As industrial AP and base station innovators, we'll advance solutions for transportation, energy and manufacturing. With smarter and more robust wireless connection solutions, we aim to facilitate the digital transformation of global infrastructure.