Industrial Wireless Zero-Roaming Solutions for Smart Factories & Warehouses

The Challenge of Industrial Wireless Connectivity

In Industry 4.0, wireless terminals are widely adopted to improve efficiency, but factories and warehouses face significant challenges:

- Unstable connections – Frequent disconnections disrupt operations.

- Poor roaming – Mobile terminals (PDA, AGV) suffer from delays and packet loss.

- High latency – Real-time data collection (MES, CNC, PLC) becomes unreliable.

Sailsky’s industrial wireless zero-roaming solutions eliminate these issues, ensuring uninterrupted production, real-time data collection, and seamless mobility for fixed and mobile devices.

1. Industrial Wireless Zero-Roaming Solution

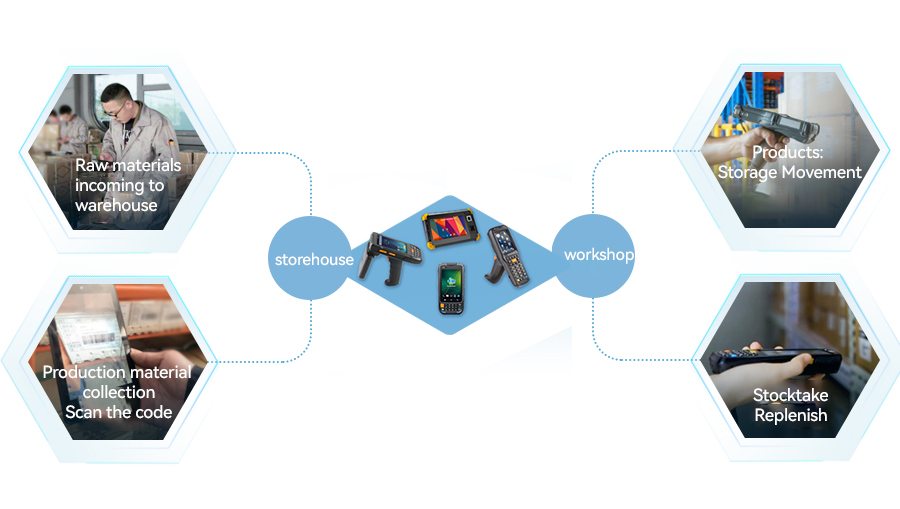

Key Applications

- PDA Handheld Terminals – Ensures continuous barcode/QR scanning for order tracking and production updates.

- AGV & Autonomous Forklifts – Prevents slowdowns, stoppages, and collisions with low-latency, zero-packet-loss wireless.

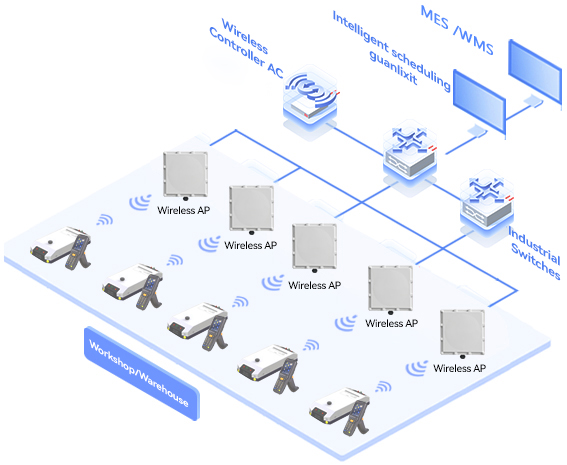

Solution Architecture

- Management Systems: WMS, MES, AGV control

- Network Infrastructure: Industrial-grade AC controllers, PoE switches, high-performance APs

- Zero-Roaming Technology: Eliminates disconnections during movement.

Result: Reliable wireless for PDA scanning, AGV navigation, and real-time data transmission, reducing downtime and improving efficiency.

2. Wireless Data Collection for Industrial IoT

Key Benefits

✔ No cabling – Lower deployment costs, easy machine relocation.

✔ High device capacity – Supports CNC, PLC, MES, and mobile terminals.

✔ AI-driven insights – Predictive maintenance, automated adjustments.

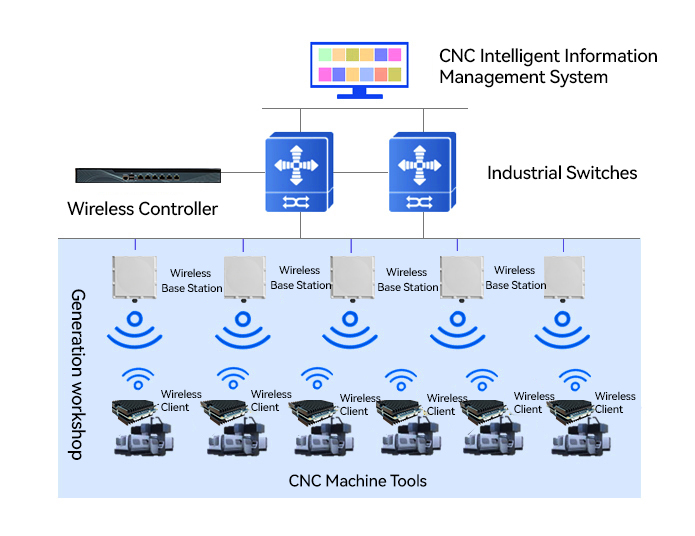

Solution Components

- Industrial Wireless Network: APs, AC, rugged switches

- Industrial Gateways: Dedicated wireless gateways for CNC/machine tools

- CNC Smart Management: Real-time analytics for equipment utilization, tool wear, and OEE tracking.

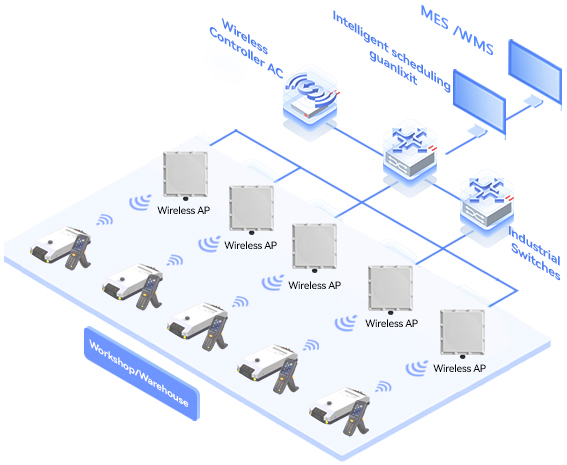

3. AGV & Mobile Robot Wireless Solutions

AGVs rely on wireless networks to resolve:

- "Where am I?" – Real-time positioning

- "Where to go?" – Path optimization

- "How to get there?" – Obstacle avoidance

Applications

- Warehousing: Smart picking, inventory management with AGVs.

- Production Lines: Heavy-load (400kg+) and light-load (20kg) material handling.

Solution Components

- AGV Control System: Intelligent scheduling software

- Industrial WiFi 6 Network: BL3000HW APs (dual-band, 3Gbps throughput)

- AGV Wireless Gateway: BL5000Air client (millisecond-level roaming, -40°C to 70°C operation)

Result: Uninterrupted production

Dual 5G uplink, CHD automatic blind spot filling, industrial-grade AP

Wireless zero roaming

Pre-roaming + dual-link technology

BL3000HW – Wifi6 AP wireless base station

In mobile handling scenarios, wireless real-time networking keeps the AGV from breaking down!

Featured Products

BL3000HW – Industrial WiFi 6 Base station

- Dual-band (2.4GHz + 5.8GHz), 3Gbps speed

- Millisecond-level roaming for AGVs, PDAs

- Industrial durability: -40°C to 70°C, 6KV surge protection

BL5000Air – WiFi 6 Client for AGVs & Robots

- Compact, rugged design for embedded use

- High-speed, low-latency connectivity

- Ideal for harsh environments (mining, warehouses, smart factories)

Why Choose Sailsky?

✅ Zero-Roaming Technology – No disconnections for mobile devices.

✅ Industrial-Grade Reliability – Stable in high-interference environments.

✅ End-to-End Wireless Solutions – From data collection to AGV control.

Upgrade your smart factory with high-performance, low-latency wireless networking today!