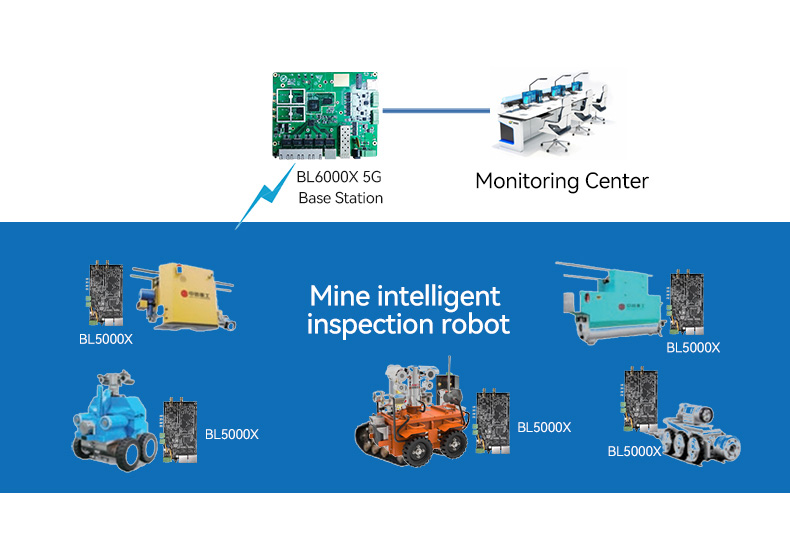

Mine inspection robot wireless coverage solution

Industry Background

Coal mine underground working faces are characterized by confined spaces, numerous mechanical devices, poor visibility, and high temperatures. Among safety incidents in underground coal mining, 80% are caused by inadequate monitoring. This highlights the critical role of real-time monitoring in ensuring safe production. However, manual inspections are challenging due to long distances and harsh conditions.

The Advantages of WiFi6 Smart Inspection Robots

With the maturation of WiFi6 technology, its applications in smart mining are becoming increasingly widespread. WiFi6-enabled inspection robots address key challenges:

- Reduced reliance on manual inspections, alleviating labor shortages and high-risk scenarios.

- Fixed-position automation and reduced mobile staffing, minimizing human exposure to hazards.

- Real-time anomaly detection and incident reporting, enhancing safety response times.

Sailsky’s WiFi6 Smart Inspection Robot features:

- Dual manual/automatic operation modes

- Integrated WiFi6 module, AI cameras, microphones, smoke sensors, wireless charging, and mobility systems

- A multi-sensor fusion monitoring platform (audio/video, vibration, temperature, smoke)

- Advanced detection capabilities:

- Belt misalignment & edge damage

- Abnormal roller noise & overheating

- Real-time drive unit temperature/vibration monitoring

- Discharge chute surveillance

Key Wireless Network Challenges in Underground Mines

While WiFi6 robots offer clear benefits, existing WiFi4 networks fall short in meeting demands:

- Comprehensive Coverage – No dead zones, multi-robot interference mitigation.

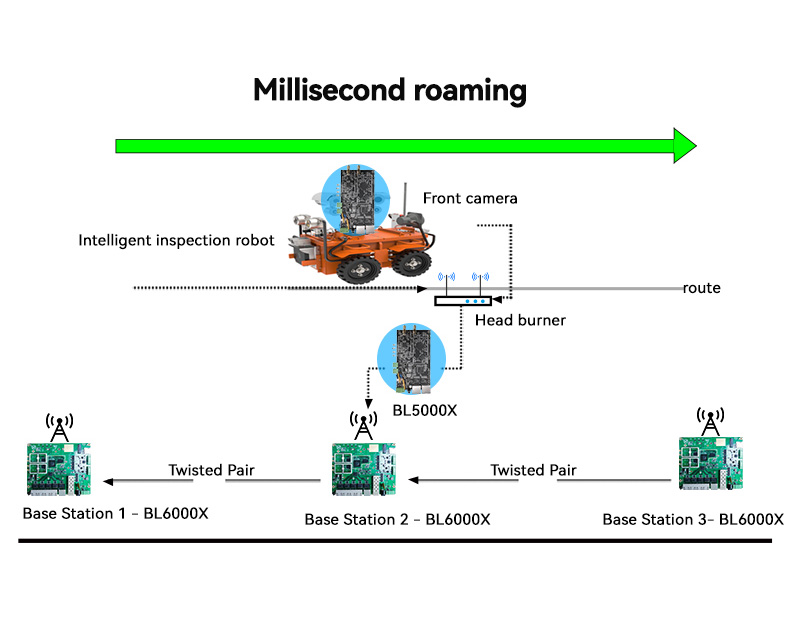

- Millisecond-Level Roaming – Seamless handover with minimal latency/packet loss.

- Compact Design – Space-efficient, industrial-grade hardware resistant to heat/EMI.

- Vibration/Shock Resistance – Durability against constant movement.

- Environmental Resilience – Dust, high temperatures, and electromagnetic interference.

Introducing the BL5000X-WiFi6 AP Client

1. 3Gbps High-Speed Connectivity

- Compliant with 802.11ax (WiFi6) standards, utilizing Qualcomm’s dual-band (2.4GHz + 5.8GHz) architecture.

- Ensures real-time data exchange for autonomous operations.

2. Intrinsically Safe Hardware

- Multi-level power/port protection for harsh industrial environments.

- Eliminates high-power consumption risks.

3. Ultra-Compact & Robust

- Terminal-style connectors for vibration resistance.

- Designed for seamless integration into robots.

4. Seamless Roaming (<1ms Handoff)

- Enhanced anti-interference performance with BL6000X base stations.

- Low-latency, high-bandwidth communication optimized for mine tunnels.

Conclusion

The Sailsky's BL5000X solves critical networking hurdles for underground inspection robots, enabling:

- Real-time environmental/equipment monitoring

- Worker safety tracking

- Predictive maintenance

By deploying these robots, mines can enhance safety protocols, improve operational efficiency, and reduce human risk—demonstrating the transformative power of smart technology in coal mining.